13 May, 2018

How Honest Is Your Tailor ?

Email me des@desmerrion.com

Find Us

Desmond Merrion Bespoke Tailor

59, Bridge Street, Castleford, WF10 1HH.

13 May, 2018

There’s a big difference between a genuine bespoke suit and a factory made suit. Understanding and knowing the difference between the two products is the key. The waters can sometimes become cloudy for the first time purchaser venturing out to commission a tailor.

This article gives potential clients the basic knowledge to differentiate between a genuine bespoke suit, and a factory made suit. Factory made suits are constantly passed off as bespoke.

1 ) Price. Unfortunately, price is a big give away to the quality of what you’re actually going to be purchasing. Cheap labour isn’t skilled, and skilled labour isn’t cheap. This doesn’t even take into account the cost of the cloth, lining, trimmings, horn buttons, rent, rates, wages etc, etc. A genuine full bespoke 2 piece suit should be starting around the £2,000 mark as a minimum if it’s going to made to a high quality in the U.K. The key words here are high quality.

2 ) Research. Research the tailor you’re thinking about using. A telephone call with a few choice questions like, “Do you cut and make your own garments”? “If not, where are your garments made“? “Do you fuse your coats”? “What’s your actual tailoring experience“?

3 ) Location. Do you want to purchase a shopping experience or a bespoke suit ? Unfortunately most of the companies that are purporting to be tailors are merely salesmen hoping to lure clients into their smart shop.

Here are some pointers to look for on the coat.

4 ) Canvas. A genuine bespoke coat has a full canvas through the front of the coat. A bespoke coat is never, ever, ever fused or glued down the fronts. Looking at one coat isn’t a confirmation of a construction method.

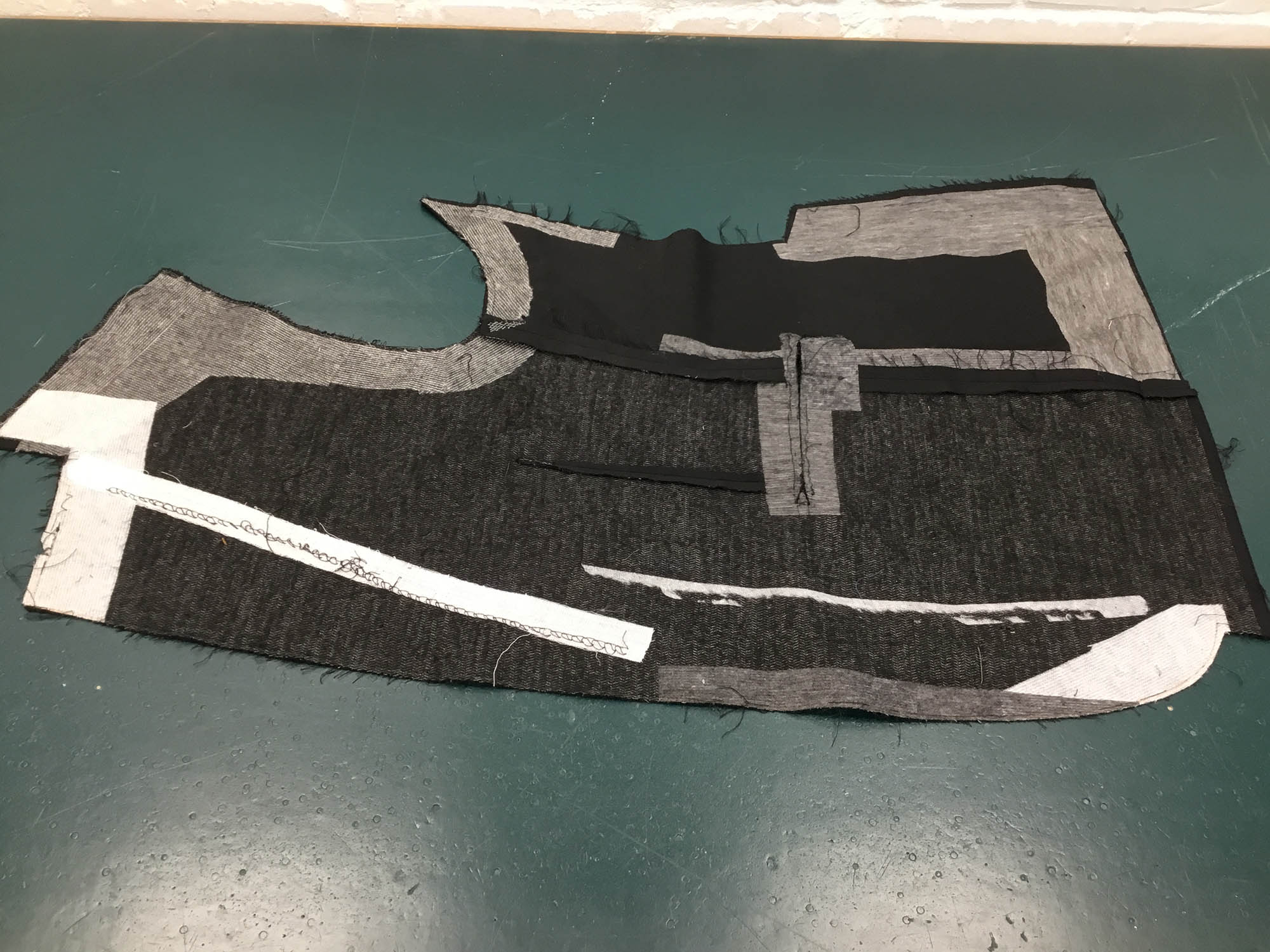

The picture below shows the inside of a factory made coat. This fusing seriously affects the drape properties of all weights of cloths, fusing makes the cloth stiff and lifeless.

The picture below shows the inside of a bespoke coat I’m working on at the skeleton baste fitting stage. You can clearly see the hand made full canvas inserted throughout the coat fronts, this canvas extends from the shoulder all the way down to the hem. Check underneath this canvas to make sure the front of the coat hasn’t been ‘skinned’ with a fusing.

5 ) The Under Collar. Zig zag stitching here is a great indicator that this coat is factory made.

the picture below shows a factory made coat, you can clearly see the zig zag stitching that’s used to make and attach the collar.

The picture below shows the underneath section of a bespoke collar Look closely on the right hand section of the picture, the very edge of the collar, you can see the irregular hand stitching of the pure silk thread. This is carrying through from the front hand stitched edges.

6 ) Pockets. The outer breast pocket on a factory made suit will have a very faint zig zag stitching down the front and back edges. The picture below shows a factory made out breast pocket with the zig zag stitching clearly visible down the end section.

7 ) Coat Edges. A factory made suit will have quite pronounced edge stitching, lift the collar or front lapels up to see underneath and you’re sure to see the nice consistent machine stitching.

The picture below shows the AMF (false hand stitched) edges on a factory made coat.

The picture below shows a section of hand stitching on a clients coat that I’ve done. This hand stitching should only be visible in certain light conditions, and only from certain angles. The hand stitched edge is very discreet, and only on the very edge of the lapel and collar. Compare the real hand stitching of the coat I’ve done to the factory stitched one pictured above.

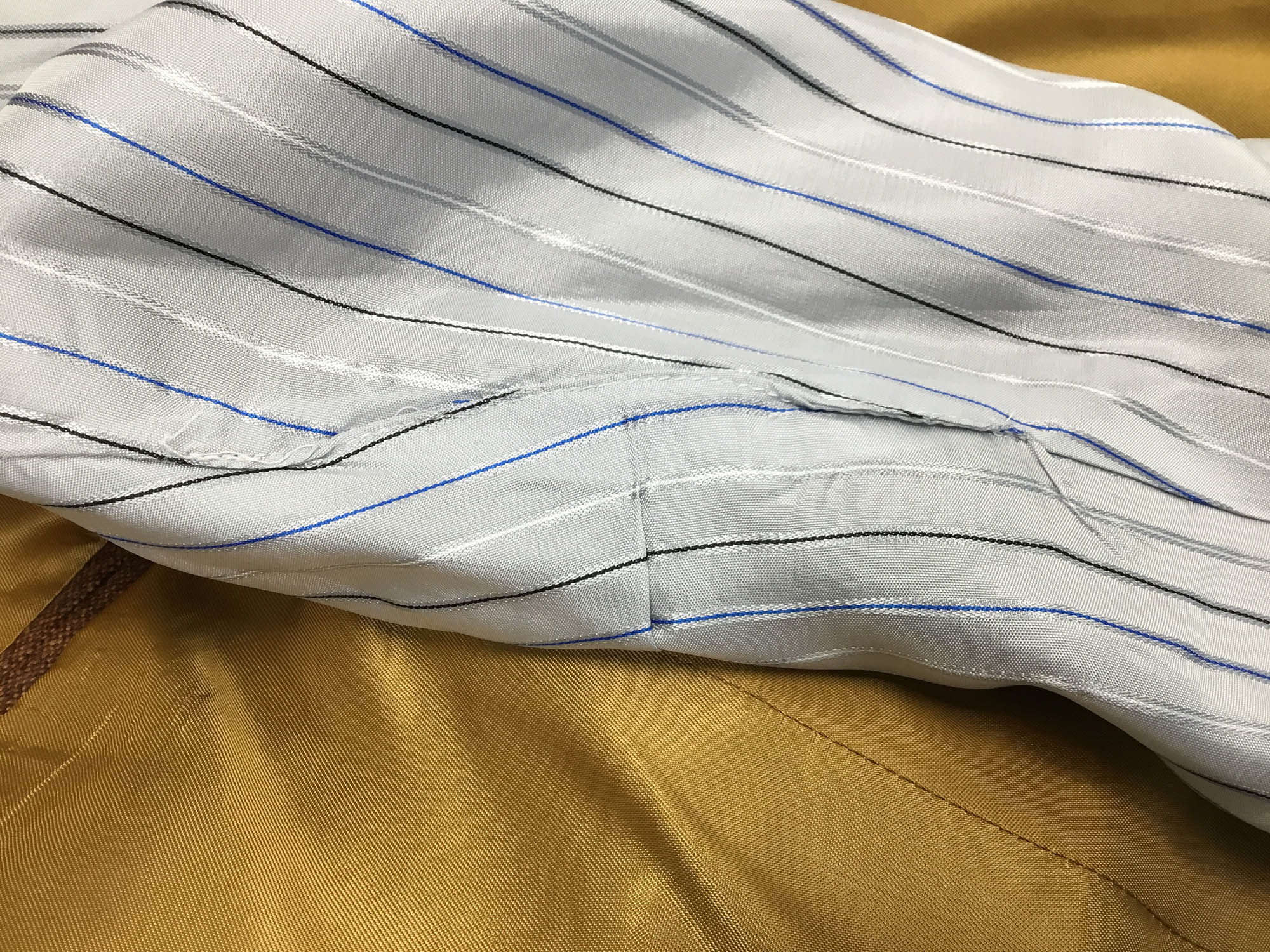

8 ) Inside Linings. A bespoke suit has all the linings completely finished by hand. Lift the lining under the hem and you’ll be able to see a cross cross hand stitch if it’s bespoke. A factory made suit will have a consistent machine stitch here. The picture below shows a bespoke coat I’ve made.

9 ) Button Holes. Bespoke suits have hand made button holes, never, ever machine made. And have a gimp inner to make them stand higher and give them strength. The reverse side of a hand made button hole is vey irregular in appearance. A factory made coat will have machine made button holes, this button hole is totally consistent on the reverse side. The picture below shows the back of a machine made button hole.

The picture below, a machine made button hole.

The pictures below show the back and front of a hand made button hole.

The picture above shows the four hand made button holes that I’ve made on a bespoke coat. A well made hand made button hole really is a thing of beauty. They stand proud, have life and are the hallmark of a quality bespoke suit. Compare the stitch density, and neatness of this hand made button hole to the lapel hole pictured above.

10) Inside sleeve linings. Bespoke coats are never, ever made this way. The picture below shows a the top stitching section on the inside section of the coat sleeve.

I hope this post has helped you to differentiate between a factory made suit and a genuine bespoke suit. You’re establishing a long, good working relationship with the tailor you ultimately may choose to use. And, hopefully I may be able to assist you with your tailoring requirements.